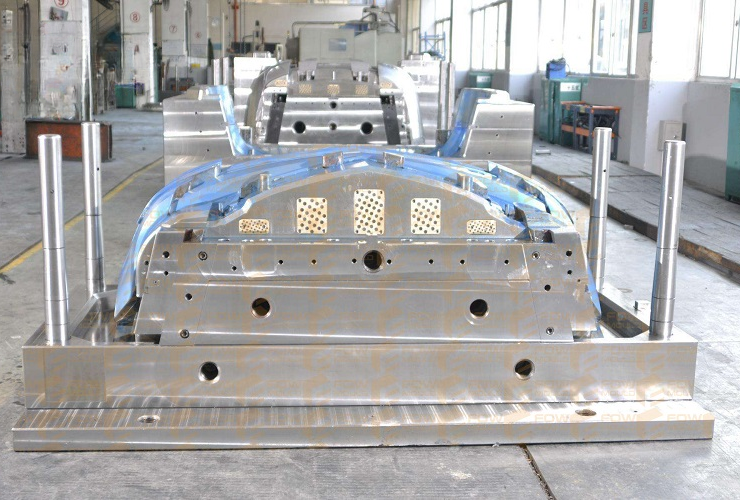

Precision Mold Making

At Black Fiber Composites, we provide precision mold making solutions engineered for high-performance industries including automotive, aerospace, marine, defense, and medical.

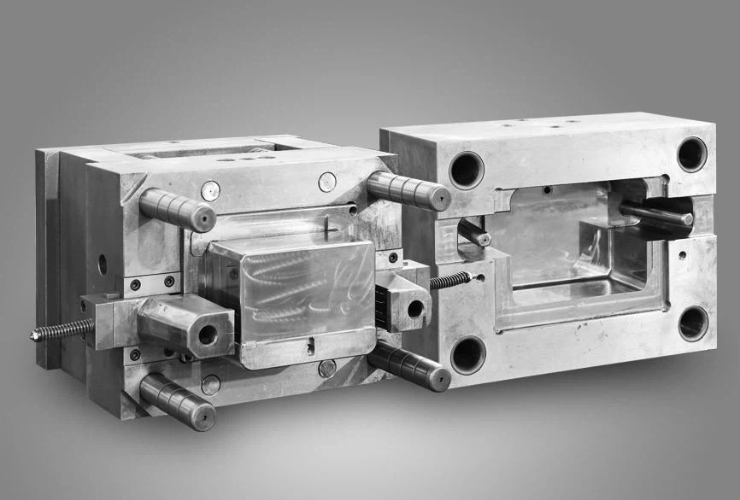

Our process starts with a detailed understanding of your component geometry, production needs, and material requirements. Whether it’s a prototype mold for rapid testing, a high-volume production tool, or a complex multi-part system, our team leverages advanced CAD/CAM software, CNC machining, and composite tooling methods to deliver molds that meet the most demanding specifications.

We specialize in creating durable, high-accuracy molds designed for composites, carbon fiber, fiberglass, and thermoplastics. With a focus on surface quality, repeatability, and production efficiency, we ensure every mold supports cost-effective manufacturing without compromising performance.

The result: molds that produce consistent, high-quality parts time after time. From one-off prototypes to long-run production tools, we partner with you to bring your concepts into scalable reality.

Our Capabilities:

✔ CNC Machined Tooling – High-precision molds for composite and polymer parts

✔ Composite Tooling – Lightweight, durable solutions for advanced manufacturing

✔ Prototype & Production Molds – From single-use prototypes to high-volume tools

Ready to Build the Perfect Mold?

Contact our team today and let’s create tooling solutions that drive performance, reliability, and efficiency in your next project.